The Problem

The Work Health and Safety legislation describes noise as any sound that has the potential to cause harm to a person’s health and safety. In Australia during the 2006 – 2007 year, the impacts of noise particularly in workplaces showed to be a clear issue for people in the workforce. Around 4000 claims were made for occupational noise-induced hearing loss in this year, where the average cost per claim equated to $11,200. These claims however do not accurately sum up the issues that the impacts of noise energy have on people, as especially with the issue of loss of hearing, it takes time for signs of damage to become obvious. Furthermore, a 2006 report indicated that one million Australians were exposed to hazardous levels of noise, ultimately accounting for 16% of adult on-set hearing loss. Due to large issue noise has within workplaces, the Australian Safety and Compensation Council has declared occupational noise-induced hearing loss as one of the eight priory disease that industries and regulators are required to address (Groothoff 2012). Finally, the impact noises have on people who are constantly exposed to it goes further than loss of hearing, with annoyance, fatigue, hypertension, heart disease, tinnitus, and depression finding to be linked with the effect of noise exposure. Furthermore, exposure to noise also impacts on people’s work productivity and increases the risk of accidents in the workplace (Safe Work Australia 2010).

The Underpinning Science

Sound energy is linked with vibration, which is the reason people have the ability to hear. When a sound is made, the air around the object that is making the sound starts to vibrate. These vibrations are sound waves. As this air moves, energy from the sound being made travels in all directions. When this vibrating air reaches a person’s ears, it causes the air inside the ears to start vibrating as well. This vibration within the ears causes the sound energy to convert into sensations which the brain interprets as a type of noise (Woodford 2016).

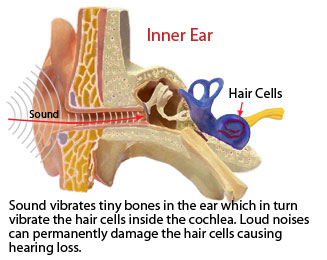

While our ears are designed for the purpose of hearing, damage can easily occur if care is not taken. Hearing loss can start to occur after exposure to a loud noise after an extended period of time. During this time, hair cells that line the basilar in the ear (shown in Figure 1) that work as sensory receptors for sound slowly become damaged. These hair cells do no regenerate once damaged. Loud noises can also damage a nerve known as the cochlear nerve, where the effect of loud noises can obstruct auditory signals from being sent to the brain (Martinez 2015).

Figure 1: Location of hair cells in ear

(Centre for Hearing, Speech and Language 2014)

Hazardous Situations

The problem with noise is that it is everywhere, and sometimes people do not have control over the noises they are hearing. There are many situations where noise can be hazardous, even outside of workplaces. Some hazardous situations include:

- At home – Mowing the lawn, loud sounds such as music from neighbouring houses, watching television on a high volume

- In workplaces – Machinery, alarms, vehicles (accelerating and backing up)

- In public – Traffic, sirens form emergency services vehicle, beeping horns, planes passing over

(Hearing Sense n.d.).

One good example of where loud noises are especially frequent are airports. Both people preparing a plane and directing it on the tarmac as well as passengers who come near the plane to board are exposed to extremely loud noises from the jet engines. For those who work around the planes, people will always see them wearing noise cancelling headgear in order to reduce the risk of hearing loss (Hearing Sense n.d.).

Measurements and Evaluation

With just about any hazard that has the potential to cause harm to someone, there are limits and thresholds associated with exposure to noise. Sounds are measured in units known as decibels. By measuring the decibels of a particular sound, it can be determined how long someone can listen to the sound before damage occurs. For sounds that measure at less than 75 decibels, it is unlikely for damage to occur even after an extended period of exposure. For sounds that measure at 85 decibels or more however, repetitive exposure to these sounds can cause damage which can lead to loss of hearing. Ultimatley, the louder a sound is means the shorter amount of time it takes for damage to occur (NIDCD 2015). Figure 2 below displays the type of sounds associated with decibel measurements, as well as the level of sound associated with each. Generally, if something is as loud as or louder than a lawn mower, ear protection is required to avoid the risk of loss of hearing (Hearing Sense n.d.).

Figure 2: Decibel units associated with noise levels

(Hearing Sense n.d.)

Safety Strategies

Legislation and Standards

- Western Australia’s workers’ compensation legislation – requires all operators of noisy workplaces to test their workers’ hearing

- The draft Model Work Health and Safety Regulations – Specifies exposure standards for noise in terms of how long people are allowed to be exposed to certain noise levels

- AS/NZS 1269 Occupational Noise Management – Provides details on noise assessment, instrumentation, and evaluation of results and noise management

- Draft Code of Practice and the relevant sections of AS/NZS 1269 – outlines the information required to comply with regulated exposure standard to prevent noise-induced hearing loss

- AS/NZS 1270 Acoustics – Provides information regarding hearing protectors

- AS 2436 Guide to Noise and Vibration Control on Construction, Demolition and Maintenance Site – Provides information on noise and vibration hazards in construction-related professions

(Safe Work Australia 2010; Groothoff 2012)

Control Measures

- Implement procedures to reduce noise made in a process (eg. Instead of hammering metal to bend it, heat the metal and bend it with pliers)

- Sound proofing parts of buildings

- Use sound absorbing materials

- Replacing older, louder equipment with new and quieter equipment

- Use hearing protection – Earmuffs, moulded earplugs, ear canal caps

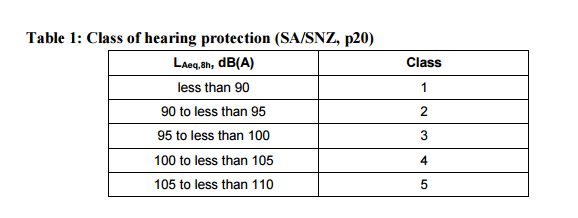

- Select appropriate hearing protection out of classes one to five according to the level of sound in a workplace (Table 1)

(Groothoff 2012)

(Groothoff 2012)

References

Centre for Hearing, Speech and Language 2014, May is better hearing and speech month, viewed 9 June 2016, http://www.chsl.org/prdocs/prhearingmonth0411.php

Groothoff, B 2012, ‘Physical Hazards: Noise and vibration’, OHS Body of Knowledge, viewed 9 June 2016, http://www.ohsbok.org.au/wp-content/uploads/2013/12/22-Hazard-Noise.pdf?d06074

Hearing Sense n.d., Causes of hearing loss, viewed 9 June 2016, http://hearingsense.com.au/causes-of-hearing-loss/

Martinez, J 2015, How can sound damage your ears?, viewed 9 June 2016, http://www.livestrong.com/article/137873-how-can-sound-damage-your-ears/

NIDCD 2015, Noise-induced hearing loss, viewed 9 June 2016, https://www.nidcd.nih.gov/health/noise-induced-hearing-loss

Safe Work Australia 2010, Occupational noise-induced hearing loss in Australia, viewed 9 June 2016, http://www.safeworkaustralia.gov.au/sites/swa/about/publications/Documents/539/Occupational_Noiseinduced_Hearing_Loss_Australia_2010.pdf

Woodford, C 2016, Sound, viewed 9 June 2016, http://www.explainthatstuff.com/sound.html